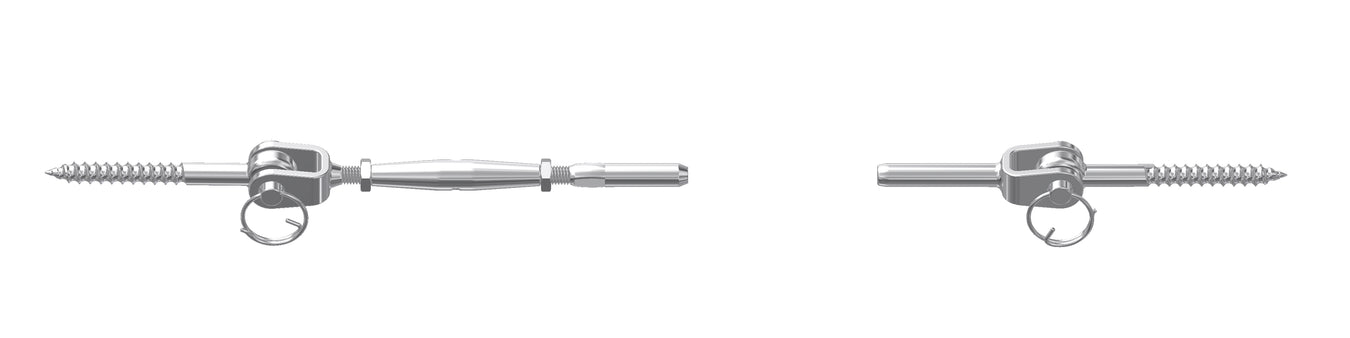

Balustrade System J - Mini Rigging Screw with Mini Swage Fork Terminal

The Mini Rigging Screw with Mini Fork Terminal Balustrade System (System J) is ideal for small runs where you wish to minimise the appearance of th...

View full details

The Mini Rigging Screw with Fork Terminal Slimline Balustrade System is an elegant looking stainless steel balustrade with an external slimline tensioner fitted to one end of the wires. This system is designed for fitting to timber posts via included Lag Eye Screws. Alternately, this system can be fitted to metal posts via Small Eye Screws fitted into Blind Rivet Nuts installed into the metal posts.

Enter the total number of System J wires required and add to cart. By using Quickshop, you can add the things you need without leaving this page.

Calculate the total length in whole metres of wire rope required (number of wires per run x total length of all runs).

Add any other accessories you need (eg lag screw driver tool and rigging screw spanner).

You'll need to send us a separate email with your required run lengths, for example:

3250 x 11, 4146 x 11, 2545 x 11 which means:

11 wires @ 3250mm, 11 wires @ 4146mm, and 11 wires @ 2545mm

Note all measurements should be inside post to inside post, with stairs measured the same way but parallel to the handrail.

The Mini Rigging Screw with Mini Fork Terminal Balustrade System (System J) is ideal for small runs where you wish to minimise the appearance of th...

View full details

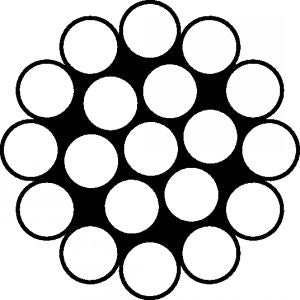

AISI 316 (marine grade) stainless steel premium quality wire rope. Made with diamond coated dies and heat annealed, this stainless steel cable is e...

View full details

Socket for driving M6 lag eye screw into timber (Nickel Plated). Not suitable for Impact Drivers

Electro-polished stainless steel C-Spanner tightening tool for easy tightening of rigging screw bodies (bottle-screws).

Used for protecting aluminium or steel posts against chafing or electrolysis with stainless balustrade wire. Black grommets enhance the appearance ...

View full details

Used for protecting aluminium or steel posts against chafing or electrolysis with stainless balustrade wire. Installation for angled grommets requi...

View full detailsNote - all pricing displayed on product pages excludes shipping and GST. These costs will be calculated at checkout.

Copyright © 2024 AAA Metal Suppliers.