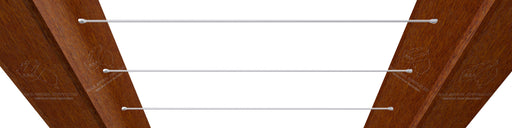

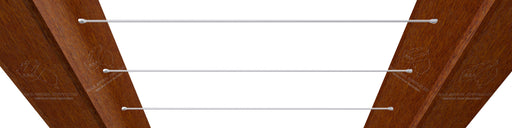

Balustrade System G - Hex Head Tensioners both ends

Our Tensioner and Swage Stud Slimline Balustrade System tensions the balustrade wire inside the post and offers a professional looking stainless st...

View full details

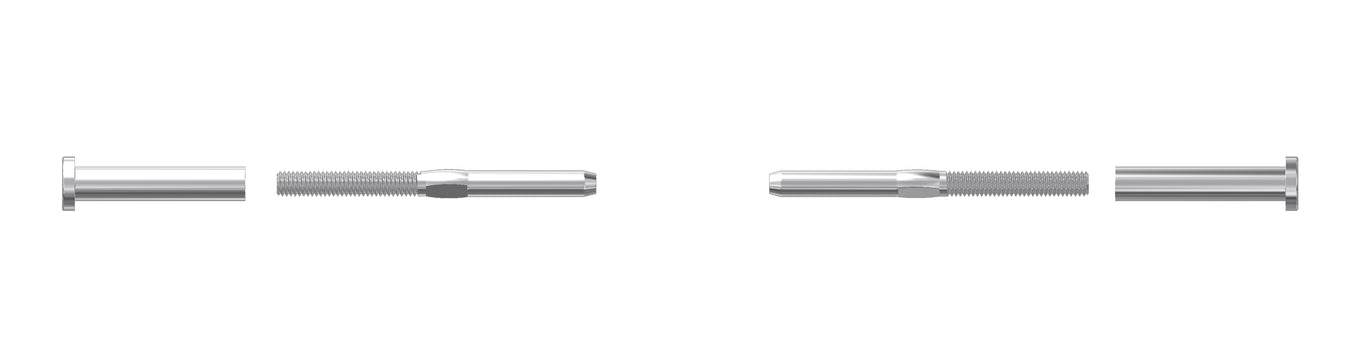

Our tensioner and swaged stud slimline balustrade system tensions the wires inside the posts from the rear and offers a professional looking stainless steel balustrade. This DIY balustrade kit is useful for both timber and steel anchor posts where the two wires do not terminate on a corner post. The tensioners are tightened using a 6mm Allen key.

Enter the total number of System G wires required and add to cart. By using Quickshop, you can add the things you need without leaving this page.

Calculate the total length in whole metres of wire rope required (number of wires per run x total length of all runs).

Add any other accessories you need (eg grommets).

You'll need to send us a separate email with your required run lengths, for example:

3250 x 11, 4146 x 11, 2545 x 10 - which means:

11 wires @ 3250mm, 11 wires @ 4146mm, and 11 wires @ 2545mm including swivel connectors.

Note all measurements should be outside post to outside post, and your project should not have corner posts if using this system.

Our Tensioner and Swage Stud Slimline Balustrade System tensions the balustrade wire inside the post and offers a professional looking stainless st...

View full details

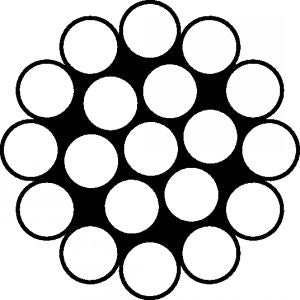

AISI 316 (marine grade) stainless steel premium quality wire rope. Made with diamond coated dies and heat annealed, this stainless steel cable is e...

View full details

Used for protecting aluminium or steel posts against chafing or electrolysis with stainless balustrade wire. Black grommets enhance the appearance ...

View full detailsNote - all pricing displayed on product pages excludes shipping and GST. These costs will be calculated at checkout.

Copyright © 2024 AAA Metal Suppliers.