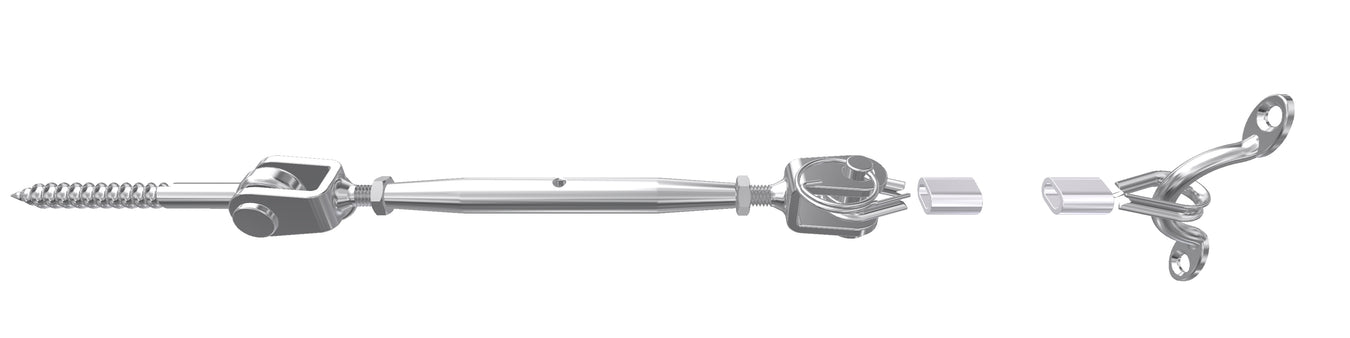

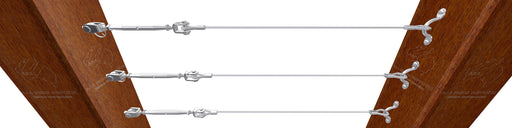

Balustrade System E - Rigging Screw with Jaw and Jaw, with Coach Screw and Saddle

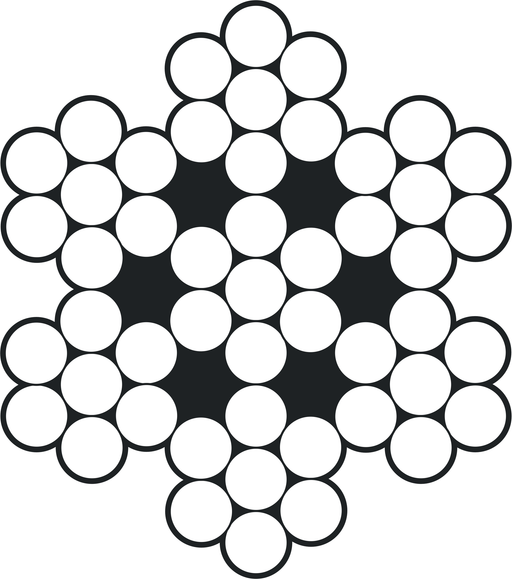

Our Ferrule Swaged Jaw/Jaw Rigging Screw System (System E) is a cost-effective stainless wire balustrade systemfor the DIY customer who wants a pro...

View full details