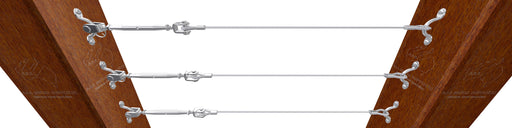

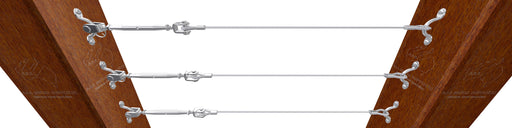

Balustrade System D - Rigging Screw with Jaw and Jaw and Saddles

The Ferrule Swaged Jaw/Jaw Rigging Screw System (System D) stainless balustrade kit is a cost-effective balustrade system for the DIY customer who ...

View full details

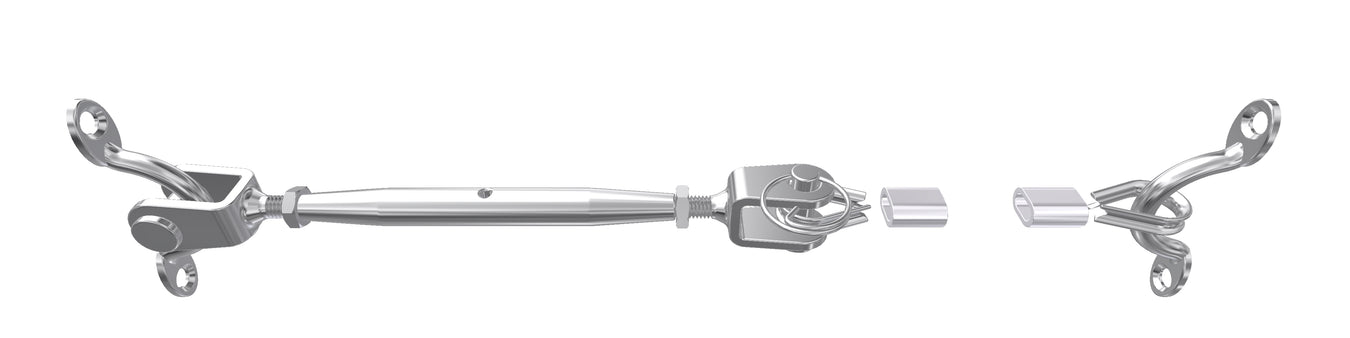

Ferrule-swaged Jaw / Jaw Rigging Screw System is a hand crimped stainless wire balustrade for DIY customers. The stainless balustrade wire is easily swaged around a thimble using a crimping tool, and is a cost effective system that still gives a more modern look.

This system can be used with timber or steel anchor posts. This is a customer-swaged system and includes all fittings required for each wire, but excludes the wire rope.

Enter the total number of System D wires required and add to cart. By using Quickshop, you can add the things you need without leaving this page.

Calculate the total length in whole metres of wire rope required (number of wires per run x total length of all runs), and add to cart.

The Ferrule Swaged Jaw/Jaw Rigging Screw System (System D) stainless balustrade kit is a cost-effective balustrade system for the DIY customer who ...

View full details

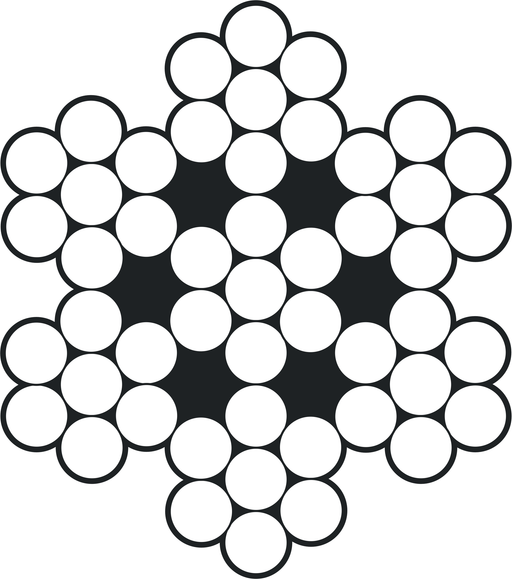

AISI 316 (marine grade) stainless steel premium quality wire rope. Made with diamond coated dies for extra brightness and heat annealed for improve...

View full details

Croc Hand Swagers and Wire Cutters are designed for crimping copper and aluminium oval and stop ferrules and cutting stainless wire rope up to 3.2m...

View full details

We have specially selected these 200mm long 'parrot beak' stainless wire rope cutters for use in our stainless wire factory because they are easier...

View full details

Used for protecting aluminium or steel posts against chafing or electrolysis with stainless balustrade wire. Black grommets enhance the appearance ...

View full details

Used for protecting aluminium or steel posts against chafing or electrolysis with stainless balustrade wire. Installation for angled grommets requi...

View full detailsNote - all pricing displayed on product pages excludes shipping and GST. These costs will be calculated at checkout.

Copyright © 2024 AAA Metal Suppliers.