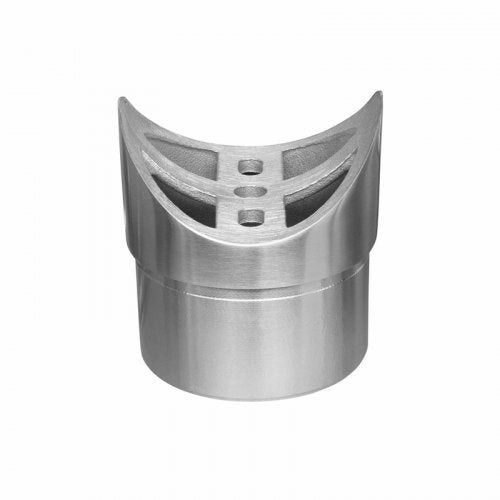

Hand Rail Kit Type 1, for Horizontal Handrail with Flush Joiners, for 50.8mm x 1.6mm tube, Satin Finish

Each Type 1 Handrail Kit Contains: 2 x Long Base Plates, 2 x post tubes for an overall handrail height of 900mm, 2 x Corner Mitre Flush Joiners, ...

View full details